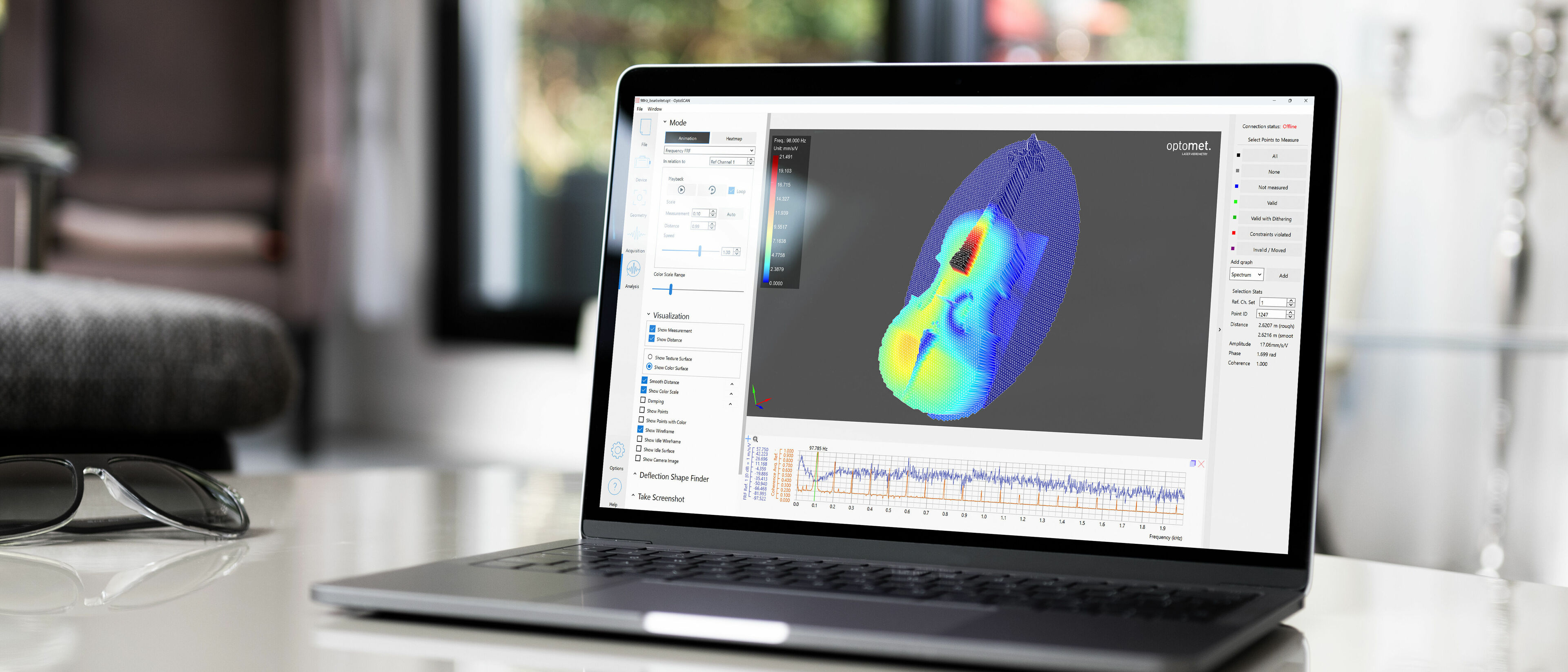

OptoSCAN

Remote control, data acquisition, visualization & analysis

In combination with the Optomet scanning laser Doppler vibrometers, the OptoSCAN software forms a complete solution for imaging vibration measurements.

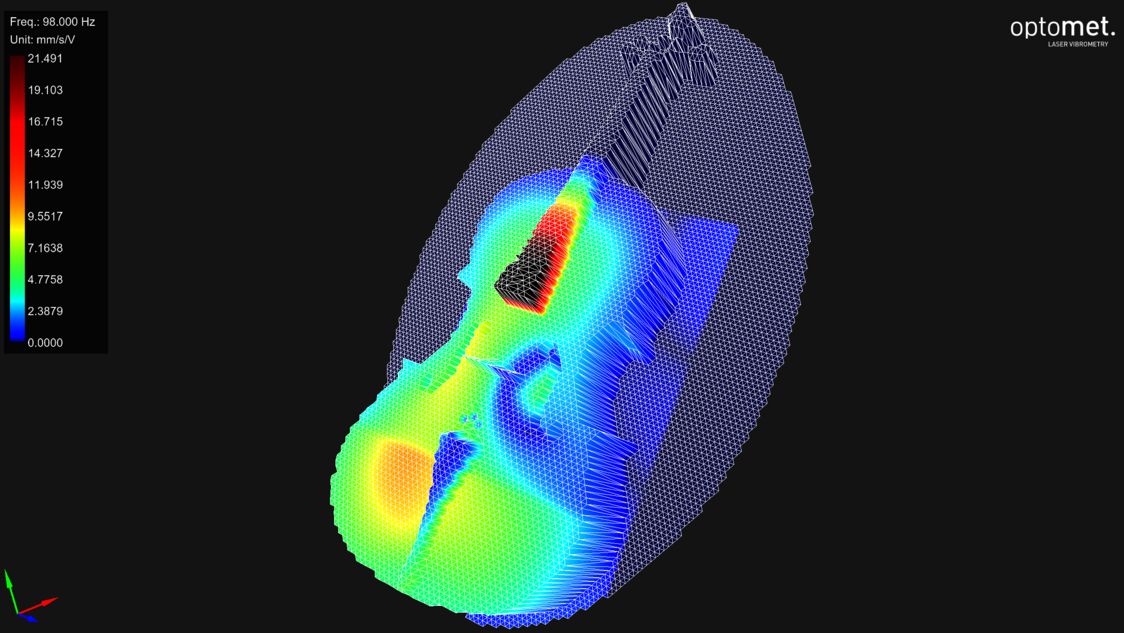

OptoSCAN combines point by point scanning data with geometry information to animate vibrations and surface waves of nearly any test object for design optimization, solving structural problems, validating FE Models and fundamental research. Data is displayed in numerous time and frequency based quantities.

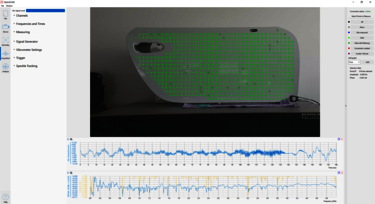

Vibrometer control

OptoSCAN remote controls all the hardware settings and components of the scanning vibrometer. The video camera and measurement laser are calibrated, decoders and measurement ranges are defined, channels for measuring and reference signals are defined, and the built-in signal generator is controlled.

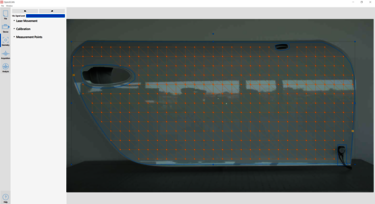

Imaging vibration measurement

Grids for the measurement points can be created and edited with just a few mouse clicks. Even complex geometries can be created easily and intuitively. After defining the measurement duration, bandwidth, frequency resolution and settings for quality requirements for the point-by-point measurements, the measurement scan can be started. Colour coding of the grid points shows the scan progress and after the scan provides information regarding the status of each point.

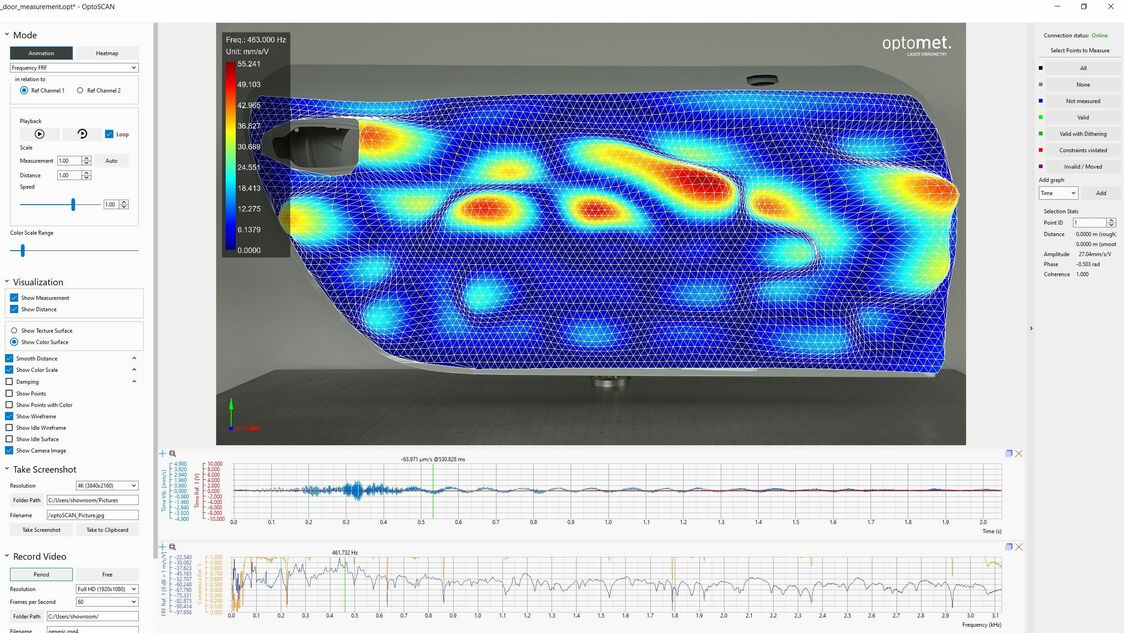

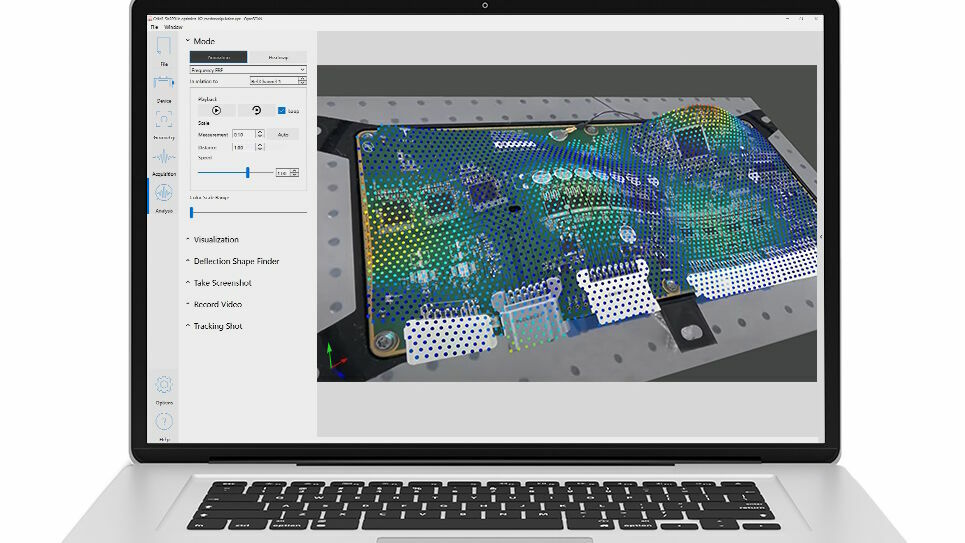

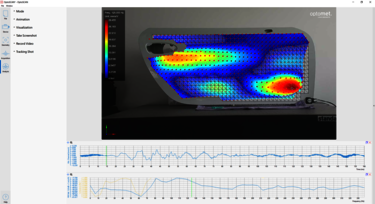

Presentation and analysis

The results are clearly displayed in diagrams, waveforms can be represented as two-dimensional maps or three-dimensional animated time profiles. A simple switch between time and frequency display enables a comprehensive analysis of the measurements. Resonances, transfer functions, vibration modes, operating vibrations or the propagation of waves are clearly visualized.

Real time measurements are displayed during the scan, and the complete analysis is possible immediately after the scan is completed without having to switch to a dedicated analysis mode.

Offline processing is possible with a desktop version of OptoSCAN. With the help of the integrated video creation tool, the results can be quickly and effectively reported or shared.

Storage and data exchange

OptoSCAN projects are clearly stored and can be read in again along with all settings for future analysis. Extensive exporting options are available for further processing of the measurement data outside OptoSCAN. Documented and open file formats enable easy exchange with programs from third-party providers, for example for modal analysis or with standard software such as MATLAB®.

Intuitive operation

Using OptoSCAN is very easy. The structure of the user interface is based on the typical workflow of a scanning vibrometer measurement: definition of the measurement project, selection of the channels and measurement ranges, definition of the geometry and measurement points, selection of the acquisition parameters and finally presentation and analysis of the measurement results. New users are guided intuitively through the measurement process, and experienced users can enjoy comprehensive functionality.

Further information

Details of the functions of the vibrometer and the OptoSCAN software can be found in the data sheet of the laser scanning vibrometer.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing