Vibration measurement: precision and applications

Vibration measurement precisely analyzes mechanical vibrations.

Vibration measurement precisely analyzes mechanical vibrations.

Vibration measurement is a central technique in modern measurement technology that enables engineers to precisely record and analyze mechanical vibrations. This method plays a crucial role in the monitoring, vibration analysis and maintenance of machines and structures in various industries.

Vibration measurement is the process of detecting and analyzing vibrations that occur in a mechanical system. These vibrations can be caused by a variety of factors, including the movement of machine parts, external forces or structural instabilities. Vibration analysis allows engineers to determine the frequencies and amplitudes of the vibrations and draw conclusions about the condition and performance of the system.

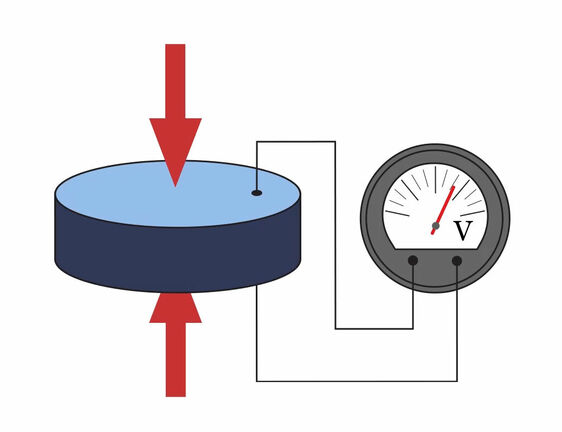

Vibrations are detected with the help of vibration sensors, such as piezoelectric acceleration sensors. These sensors convert mechanical movements into electrical signals. When the object to be measured vibrates, the sensor generates electrical charges due to the mechanical stress. These signals are amplified and analyzed to determine the movement characteristics of the object. A typical vibration measurement device integrates these sensors and provides a comprehensive platform for vibration measurement and analysis.

Vibration measurement makes it possible to identify potential problems at an early stage and take maintenance measures. Regular vibration measurements can identify anomalies and signs of wear before they lead to major failures. This is particularly important in industrial manufacturing, aerospace and construction, where the safety and reliability of machinery and structures are essential.

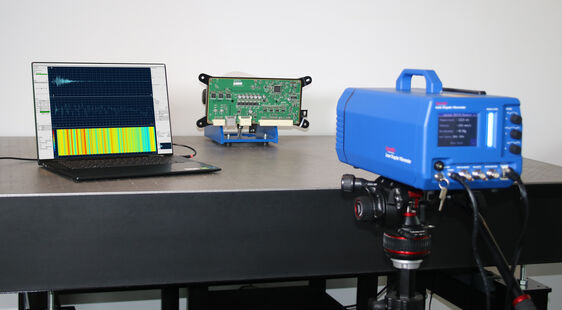

Vibration measurement is usually carried out by placing vibration sensors at critical points in the system. These sensors record the mechanical vibrations and forward the data for analysis. Fast Fourier Transformation (FFT) is a common method for analyzing this data as it breaks down the time domain signals into their frequency components. This enables a detailed analysis of the vibration frequencies and amplitudes.

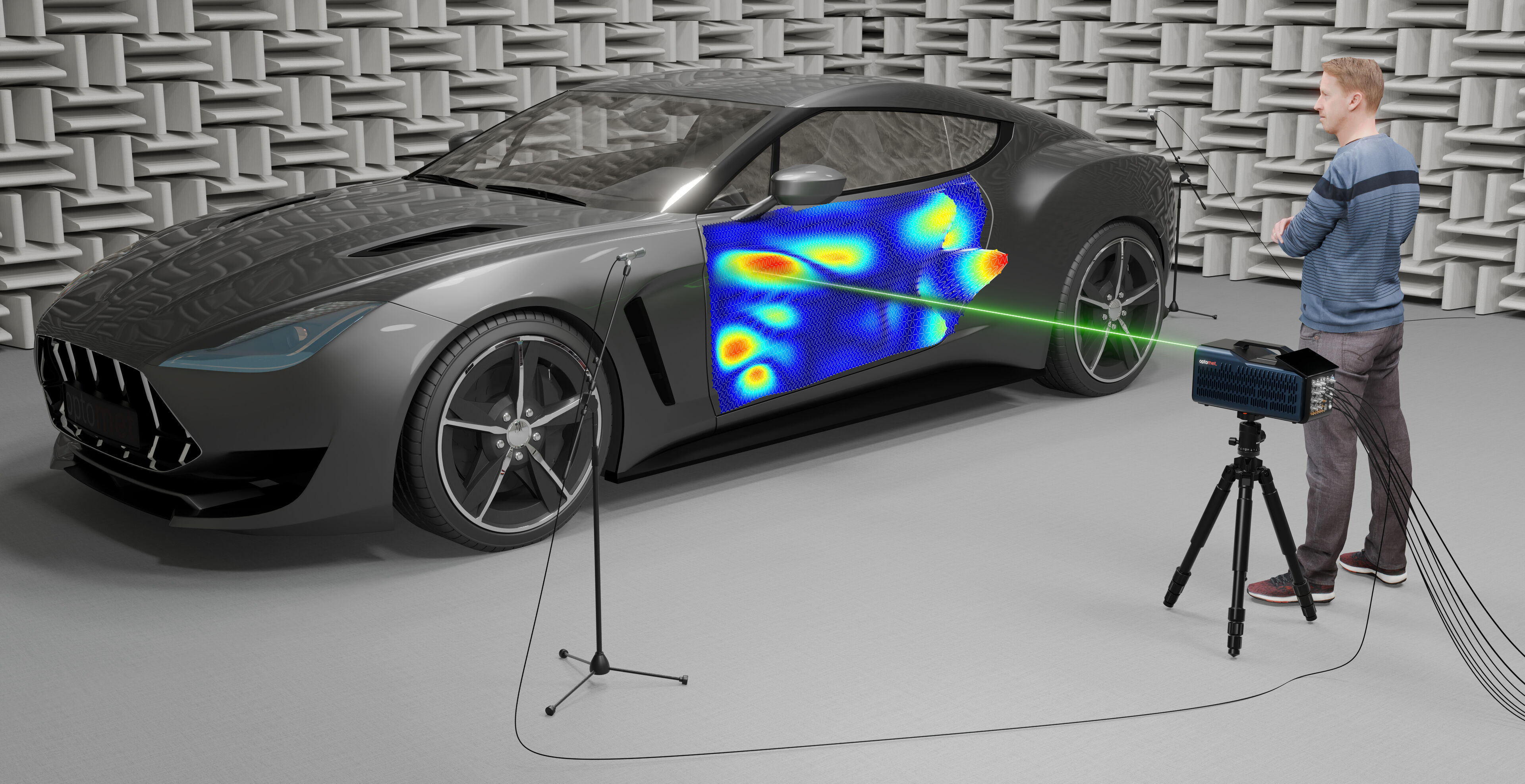

A laser Doppler vibrometer (LDV) offers a non-contact method for precise vibration measurement. Based on the Doppler effect, a laser beam is focused on the surface to be measured. When the surface moves, the frequency of the reflected laser light changes. This frequency shift is analyzed using an interferometer. The optical signal is then converted into an electrical signal by a photodetector. Demodulation of the signal enables precise conclusions to be drawn about the movement of the surface. This technology offers maximum precision and is used in many demanding applications, such as in aerospace and microstructure technology.

An outstanding example of advanced vibration measurement devices is the SMART Scan+. This compact system offers optimal signal processing and advanced accuracy, making it ideal for detailed vibration analysis.

Vibration measurements are used in many areas. In industry, they are used for monitoring and quality assurance of production processes. In research and development, they help to investigate material properties and develop new technologies. In the automotive industry, vibration measurements enable the analysis of NVH (noise, vibration, harshness) and contribute to improving driving comfort. Vibration measurements are also important in medicine, for example for investigating medical devices and biological structures.

Vibration measurement is constantly evolving, driven by technological innovations. Modern vibration measurement devices and laser Doppler vibrometers offer increasingly higher precision and user-friendliness. The integration of intelligent software and advanced sensor technologies makes it possible to record and analyze even complex vibration patterns in detail. These developments are setting new standards in vibration measurement technology and expanding the range of applications in various industries.

Further topics on basics & measurement technology