Laser Vibrometer: Precise vibration measurement

Laser vibrometers for high-precision, non-contact technology in a wide range of applications

Laser vibrometers for high-precision, non-contact technology in a wide range of applications

A laser vibrometer is a high-precision measuring device for non-contact measurement of mechanical vibrations. By using laser Doppler vibrometry (LDV), it provides accurate measurement of frequencies and amplitudes of object vibrations. This technology is used in a variety of scientific, industrial and medical applications and sets new standards in vibration measurement technology.

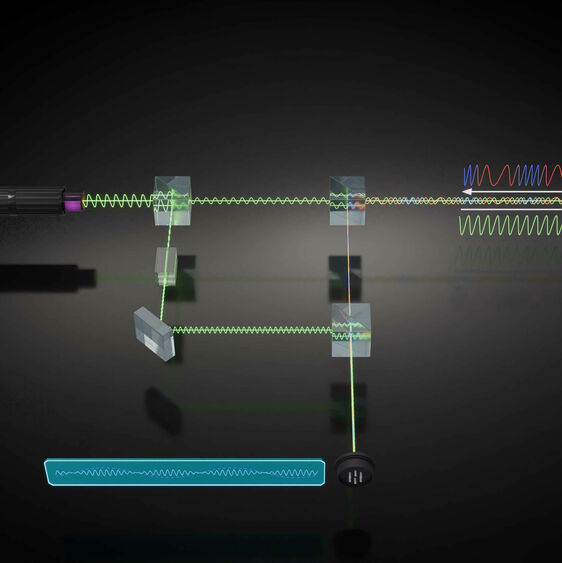

Laser Doppler vibrometry is based on the principle of the Doppler effect. A laser beam is focused on the surface to be measured. If the surface moves, the frequency of the reflected laser light changes. This frequency shift is analyzed using an interferometer and converted into a voltage signal or a digital data stream.

The core of a laser vibrometer is the interferometer, which uses optical interference to measure the movements of the surface. A measurement beam and a reference beam are superimposed. Movements of the measurement object generate characteristic light-dark patterns on the detector, which are used to determine the vibration speed and direction.

These devices measure the vibrations at a single point. They are ideal for simple and fast measurements in modal analysis and quality assurance. One example is the SMART Single+, which enables precise and efficient measurement thanks to its compact design and user-friendly operation.

These devices use computer-controlled mirrors to direct the laser beam over the measurement object. This enables measurement at several points and the creation of detailed vibration maps. The laser beam is deflected by two mirrors, which are controlled by the computer, making it possible to measure vibrations over a large area.

Non-contact and non-reactive: As the measuring method does not require physical contact, the object being measured is not affected.

High precision: Laser vibrometers enable measurements in the range from femtometers up to very high frequencies of up to 6 GHz.

Wide range of applications: From microstructure analysis to monitoring large structures such as bridges and buildings.

Robustness and adaptability: Modern devices are suitable for use in different environments, including vacuum chambers and under extreme conditions.

In industry and the automotive sector, laser vibrometers are used to monitor and optimize production processes. They measure machine vibrations and enable the early detection of irregularities, thus avoiding expensive breakdowns. Laser vibrometers are particularly essential for NVH analysis (noise, vibration, harshness) of vehicle components to improve driving comfort and acoustics.

In the aerospace industry, non-destructive testing of aircraft components is essential. Laser vibrometers are used to ensure the structural integrity and reliability of aircraft and spacecraft. The Optomet SMART Scan+ series can be used to measure the precise vibration characteristics of components, which is essential for modal analysis and lifetime estimation.

In the field of medical technology, laser vibrometers enable the non-contact examination of biological structures such as the eardrum. This technology offers decisive advantages in the diagnosis and testing of medical devices and in the non-destructive analysis of living organisms.

Laser vibrometers are also the solution for specific problems in other areas of application.

Modern laser vibrometers integrate advanced technologies and offer user-friendly, compact devices that combine the entire laboratory environment in a single system. These systems use innovative interferometer designs to ensure maximum precision and efficiency and allow customization to specific customer requirements.

Continuous development in laser vibrometry eliminates noise and significantly improves optical sensitivity, enabling more accurate measurements on all surfaces. Recent developments such as Optomet's SMART series set new standards in vibration measurement technology by integrating smart technologies and modular systems that allow for customized configuration.

Laser vibrometers are indispensable tools in modern vibration measurement technology. Their ability to measure precisely and without contact makes them an essential instrument in many scientific and industrial applications. As technology continues to advance, laser vibrometers will continue to set new standards in measurement technology and expand their range of applications. Their versatility and high precision make them a key tool for future innovations in various industries.

Further topics on basics & measurement technology