Laser sources for precise vibration measurements

An introduction to the world of lasers and vibrometers

An introduction to the world of lasers and vibrometers

The type of laser source plays a crucial role in precise non-contact vibration measurement, especially in the development of advanced laser Doppler vibrometers (LDVs) for various applications. In the following, we will take a closer look at two types of laser sources and discuss their applications in vibrometry.

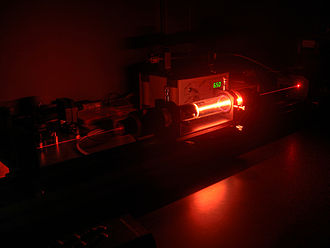

Helium-Neon laser sources (HeNe laser sources) have been used for conventional laser Doppler vibrometers for many years and, thanks to their unique properties, are a useful tool for non-contact vibration measurement. The helium-neon laser is an indispensable tool in vibrometry thanks to its unique properties and versatility. The gas laser consists of a gas mixture of helium and neon and emits red light with a wavelength of 632.8 nm.

Commercial HeNe lasers are relatively small devices with cavity lengths usually between 15 and 50 cm, but sometimes up to about 1 meter to achieve the highest powers, and optical output powers between 0.5 and 50 mW. The exact wavelength of red He-Ne lasers in vacuum is 632.991 nm and is refracted to about 632.816 nm in air.

The beam emitted by HeNe lasers is visible to the human eye and can be aligned without any aids. Its comparatively short wavelength makes it possible to focus the laser beam precisely on a very small measuring point, which makes the HeNe laser particularly suitable for measuring microstructures and fine details. Vibrometers with HeNe lasers are regularly used if a sufficient signal is scattered back from the measurement object, the measurement surface has sufficient reflectivity or measurements are to be taken through water, as light with a wavelength of 633 nm penetrates water almost unhindered.

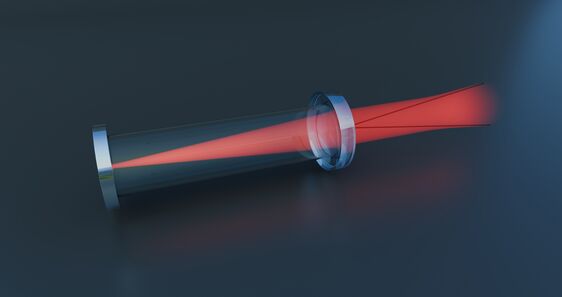

Optomet relies on the latest and most advanced short wavelength infrared (SWIR) laser technology for the best signal quality for demanding measurement tasks.

The SWIR laser used emits invisible light at a wavelength of 1,550 nm with an output power of up to 10 mW. This provides ten times the output power of a HeNe laser. In combination with photodetectors with an efficiency of more than 98%, this results in a 20 dB higher signal-to-noise ratio (SNR) in comparison to conventional HeNe LDVs.

Despite the higher laser power, the SWIR laser has the highest laser protection class 1 according to EN 60825-1 and is therefore eye-safe. The liquid in the eye absorbs the infrared light and thus protects the eye. The invisible measuring beam is positioned by means of a coaxially guided green pilot laser (wavelength: approx. 532 nm). The power of the pilot laser is limited to 1 mW, resulting in classification to laser protection class 2 in accordance with EN 60825-1. Therefore, Optomet SWIR vibrometers always have laser protection class 2 for the overall system.

Nowadays, besides some applications where the unique properties of HeNe lasers are required, SWIR lasers are the optimal choice for Laser Doppler vibrometry and Optomet takes the leading role in SWIR vibrometry. Due to a combination of higher output power and more sensitive photodetectors, SWIR vibrometers offer a higher SNR and are therefore particularly suitable for demanding measurement tasks where vibrometers with conventional laser sources reach their limits. Measuring even on dark, rough, curved or other surfaces with low reflectivity, infrared vibrometers eliminate the need to treat the surface. Vibration measurements over long distances are also the undisputed domain of SWIR LDVs, as well as measurements on glowing hot surfaces and on biological tissue. High temperature stability and a long service life offer additional advantages. All these characteristics also apply to the new SMART series from Optomet.

Laser Doppler vibrometers (LDVs) are indispensable tools in many fields, including engineering, materials science, biology, medicine and many more. They enable non-contact, precise measurements of oscillations and vibrations on surfaces of various materials and structures.

From quality control in manufacturing to the examination of biological tissue, the applications of LDVs are almost limitless. Thanks to their ability to provide high-resolution data in real time, LDVs are an indispensable tool in research, development and quality control.

Vibrometry is a constantly evolving field, driven by technological innovations and new research findings. Continuous improvements in laser sources and LDV technologies are enabling more precise measurements and an even wider range of applications.

From classic HeNe lasers to modern infrared lasers, the choice of vibrometers is more diverse than ever before. At Optomet, we are constantly working to improve our products and services and offer our customers innovative solutions for their measurement tasks.

Further topics on basics & measurement technology