Wind tunnel testing

With our newest generation of laser Doppler vibrometers (LDVs), the Optomet SMART series, we offer a comprehensive solution for precise vibration measurement in wind tunnels. LDVs enable non-contact vibration measurements and can be used for various applications in fields like the automotive industry, aviation or civil engineering. Cars, airplanes, high-rise buildings and bridges, or their models can now be analyzed in wind tunnels – holistically, in real time and with maximum accuracy.

Automotive industry: Optimization of vehicle stability

The optimization of vehicle stability and aerodynamics is a decisive factor for the success of modern vehicle developments. With the SMART series from Optomet, vehicle models can be examined in the wind tunnel to obtain precise data on vibration behavior and air flows. Non-contact laser Doppler vibrometry enables 360° vibration measurement of even the smallest vibration on entire vehicles without affecting the aerodynamic flow.

Advantages for vehicle development

Increased comfort:

By precisely recording and analyzing vibrations, unpleasant vibrations that affect the interior of the vehicle can be minimized. The result is less noise and vibration inside the vehicle, which significantly improves ride comfort.

Optimization of driving dynamics:

Vibrations that occur while driving due to external influences such as wind or road conditions can be simulated and optimized using the measurements in the wind tunnel. This leads to better driving stability and an overall smoother driving experience.

Maintaining structural integrity:

Despite the optimization of aerodynamics and vibration behavior, the structural integrity of the vehicle is not compromised. The SMART series captures vibrations precisely, allowing engineers to keep the structure of the vehicle stable and safe.

Improved aerodynamics:

While performing the non-contact vibration measurements with the SMART full body vibrometry system, aerodynamics can be evaluated at the same time as the air flow is not obstructed. Furthermore, air resistance can cause vibrations meaning that vibration data can be used to optimize the shape of the vehicle and minimize drag, which in turn increases energy efficiency.

_6db5279450.jpg)

Aviation: Reduction of noise and vibrations

In aviation, the reduction of noise and vibrations plays an important role in the safety and comfort of passengers as well as the efficiency of aircraft design. The SMART series from Optomet makes it possible to precisely record even the smallest vibrations on aircraft models in the wind tunnel. Thus, structural weaknesses can be identified at an early stage, enabling targeted improvements.

Advantages for aircraft development:

Reduction of noise emissions:

By precisely recording vibrations in critical areas of the aircraft, such as the wings or engines, disruptive noises can be detected at an early stage and reduced in a targeted manner. This leads to a significant improvement in the background noise in the cockpit and passenger cabin, which considerably increases comfort for passengers and crew.

Vibration optimization for greater efficiency:

The SMART series measures vibrations caused by aerodynamic loads and mechanical stresses in flight. This detailed data can be used to optimize the structure of the aircraft and thus increase efficiency. Less vibration means less material fatigue and a longer service life for aircraft components.

Increase safety and reliability:

By monitoring and analyzing even the smallest vibrations, the SMART series helps improve structural safety. Engineers gain deeper insights into the behavior of the aircraft under load and can make informed decisions that increase the overall reliability of the aircraft.

Improved aerodynamics:

Vibrations not only affect noise, but also the aerodynamic performance of an aircraft. With the SMART series, developers can identify areas of the aircraft that cause vibrations and improve aerodynamics through targeted adjustments.

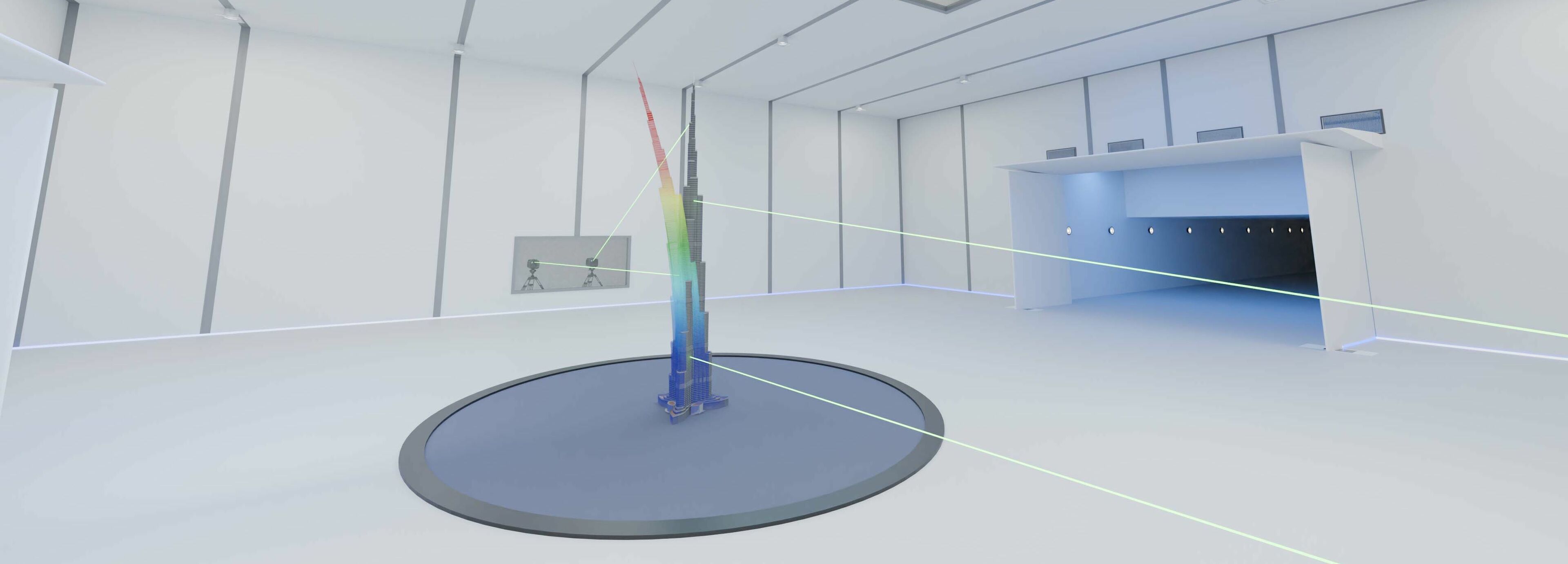

Building industry: Structural analysis of high-rise buildings

The analysis of vibrations plays a central role in the construction industry in order to ensure the stability and safety of high-rise buildings. The SMART series from Optomet is used specifically to record vibrations on high-rise building models in the wind tunnel. This advanced technology provides precise data on the behavior of structures under wind loads and enables well-founded optimization of the building design.

Advantages for high-rise development:

Stability and safety under wind load:

The SMART series captures large movements and small vibrations on high-rise models and provides valuable information on how the structure reacts to strong wind forces. Engineers can use this data to ensure that the building remains stable in extreme weather conditions and does not exhibit dangerous fluctuations.

Early detection of weak points:

Precise vibration maps can be used to identify weak points in the building structure at an early stage. These areas can then be specifically reinforced to ensure the long-term stability and safety of the building.

Optimization of building designs:

With the detailed vibration data collected by the SMART series, architects and engineers can adjust the design of the high-rise building to make it less susceptible to wind forces. This leads to improved structural efficiency and a safer end product.

Simulation of real conditions in the wind tunnel:

The SMART series offers the possibility to simulate the behavior of a building model under realistic wind conditions. The data obtained enables an accurate prediction of how the high-rise building will react to wind and other external forces in the real world.

Civil engineering: Structural analysis of bridges

The analysis of vibrations on bridges plays a crucial role in ensuring the stability and safety of these complex structures. The Optomet SMART series makes it possible to perform precise vibration measurements on bridge models in the wind tunnel to obtain valuable data on their behavior under wind loads. These findings help engineers to improve structural integrity and identify potential weaknesses at an early stage

Advantages for bridge development:

Safety assurance under wind loading:

The SMART series records the vibrations exerted on bridge structures by wind and other external influences. The precise results help engineers to ensure that the bridge remains stable even under extreme wind conditions and that no dangerous vibrations occur.

Early detection of structural weaknesses:

By analyzing the vibrations in detail, potential weak points in the bridge structure can be identified at an early stage and strengthened in a targeted manner. This increases safety and minimizes the risk of structural damage or failure.

Longer bridge life:

Precise analysis of vibrations makes it possible to identify areas that could suffer from material fatigue over time. Through targeted adjustments and reinforcements, the service life of the bridge can be extended and its resistance to wind and other external influences increased.

Simulation of real wind conditions:

The SMART series makes it possible to test bridge models under realistic wind conditions in the wind tunnel. These simulations provide valuable data that enables an accurate prediction of how the bridge will react to wind and other dynamic forces in real operation.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing