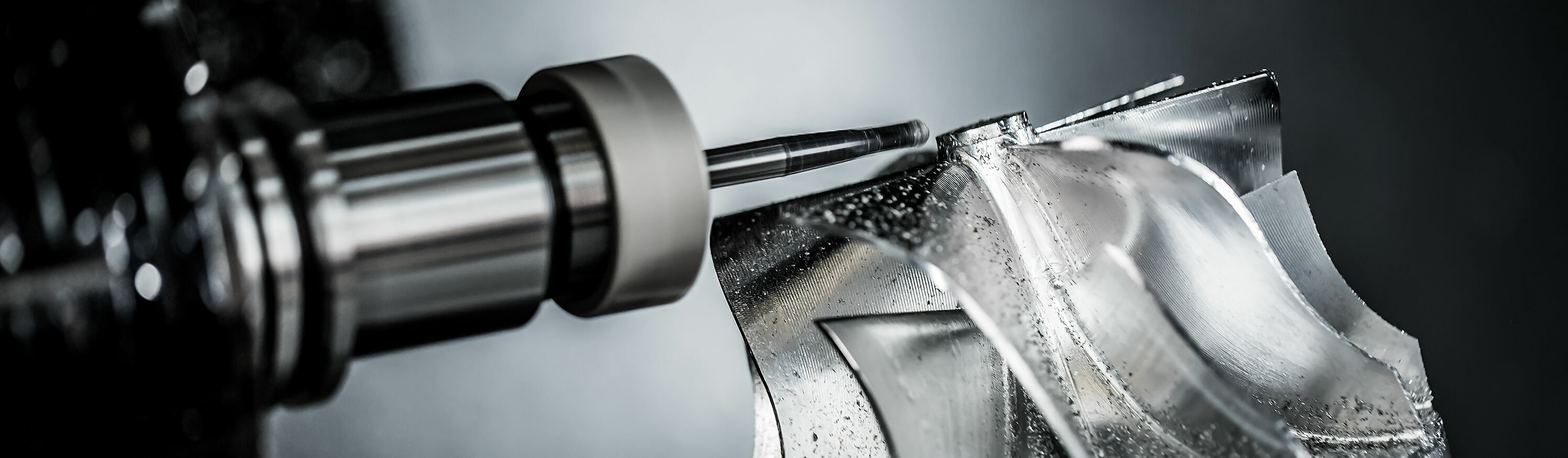

In order to acquire the dynamic behavior or the operating deflection shape of different kinds of machinery and equipment, Optomet laser Doppler vibrometers are the perfect measurement tools because they are flexible enough to measure all types of vibrations quickly and without contact even over long distances, rotating parts or glowing surfaces. Manufacturers from many industries with different products (from drilling machines to power plant generators) rely on Optomet.

Tools & Machinery

Operational Vibration Analysis of Machines

The operational vibration analysis determines the vibration behavior of an object in a specific operating state. In contrast to the modal analysis, there is no artificial vibration excitation e.g. with the help of a shaker. Typically, operation excitation is limited to certain frequency bands.

An Optomet scanning vibrometer can measure the operational mode of vibration of an object and animate them by taking a large number of measurements at different points during operation. The combination of high spatial, amplitude and frequency resolution enables the developer or user to understand the behavior of the machine or system in detail and to optimize it in a targeted and efficient manner.

The investigation of such operating vibrations is used both for product development and for condition monitoring of plants and machines.

Practical Examples

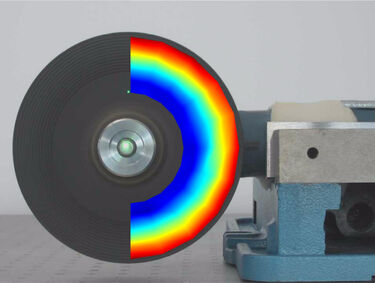

Cutting discs are made, for example, of diamond-studded metal or resin-bonded aluminum oxide and sometimes have very rough surfaces. While measurements of vibrations on rotating objects are a challenge in themselves, they become even more demanding due to the high roughness of the surface.

Even under these difficult conditions, Optomet’s scanning laser Doppler vibrometers can clearly identify the vibration modes of the rotating disks.

Vibrations of a rough rotating grinding wheel

Europe: 9:00am - 5:00pm (UTC+1)

Americas: 3:00am - 12:00pm (UTC-5)

Asia: 3:00pm - 0:00am (UTC+8)

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing