The structural integrity of aircraft is critical to safety and performance. Optomet's Laser Doppler Vibrometers enable high-precision, non-contact vibration measurements specifically designed to analyze aircraft wings, riveted joints and envelope strength. With these technologies, even the smallest deformations and vibrations can be detected in real time, helping to increase structural durability and optimize maintenance cycles.

Precise vibration measurement for aerospace structures

Analysis of wing vibrations

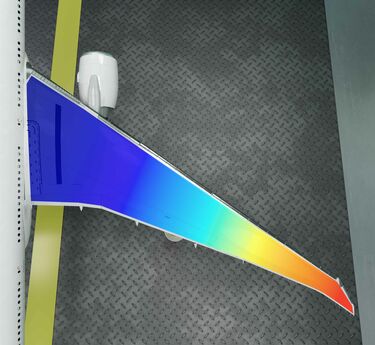

During flight operations at high speeds, the wings of an aircraft are exposed to considerable vibration and deformation. Deformations can occur in a range between a few and a few hundred millimeters, whereas vibrations can range from nanometers to up to several hundred micrometers.

No conventional measuring instrument is able to cover such a measuring range of more than 160 dB in a single measurement. With the Optomet Nova Sense in connection with OptoGUI software, it is possible for the first time to measure the deformations and vibrations at the same time with a dynamic range of more than 220 dB. The superior performance of the Optomet Nova Sense has been confirmed by measurements on airfoil models in the wind tunnel.

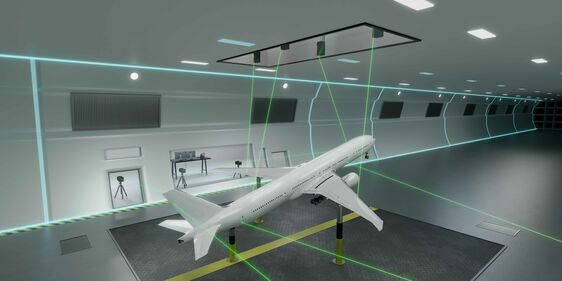

Precise vibration analysis in the wind tunnel

In a modern wind tunnel, an aircraft model is tested for vibration behavior using laser Doppler vibrometers from Optomet. The precise positioning of the lasers enables the structural vibrations and deformations of the aircraft to be fully recorded under various aerodynamic conditions. The non-contact measurement technology allows engineers to analyze critical points on the wings, fuselage and joints in detail. This data is crucial for identifying weak points at an early stage and optimizing the structural strength and safety of the aircraft. The SMART series from Optomet ensures that complex vibration analyses can be carried out in real time and with the highest precision.

Testing riveted joints with laser vibrometry

With the steady increase in air traffic, the need for fast and reliable inspection methods that check the integrity of the material connections increases. Even though glued connections are becoming increasingly popular, riveted connections still make up the majority of connections in aircraft. Today's standard inspection regulations require rivets to be visually inspected by certified personnel. These inspections are time consuming, prone to errors, and early stages of errors are usually not recognized.

Therefore, there is great interest in modern approaches that enable reliable and standardized inspection of riveted joints and at the same time shortening the downtime of planes.

Optomet scanning laser Doppler vibrometers (SLDV) enable non-contact, reliable and, above all, objective early detection of loose rivets. If the corresponding aircraft part, which is connected to rivets, gets excited in a broad frequency band, SLDVs can record and analyze the complete vibration behavior of its surface within the analysed frequency spectrum. Mapping the areas to be inspected around the rivet connections with suitable evaluations provides meaningful information on the condition of the rivets, such as the mean amplitude of the vibrations, the coherence distribution of the measurement data or the frequency transfer functions between different points on the surface.

A significant deviation of these quantities at closely localized positions compared to the rest of the surface allows a direct assessment of whether there is a tired riveted joint at these points, even if the riveted joint is not even visually recognizable. The extent of the deviation also allows a statement on the degree of fatigue of the rivet connection and thus also a decision as to whether this rivet should be replaced immediately or if the connection still has sufficient strength for further operation and an exchange can be carried out within a regularly planned maintenance schedule.

In addition to analyzing aircraft structures, Optomet offers high-precision solutions for measuring the vibration of individual turbine blades. These special applications help to optimize the vibration behavior of turbines and detect possible resonance problems at an early stage. For detailed information, please visit our turbine analysis page.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing